Initial Situation

Our client, a Tier 1 automotive supplier, must enhance productivity, lower prices, and reduce costs in a volatile market environment that demands additional flexibility. At the same time, resources for new production equipment are limited, with new purchases often planned just one year in advance.

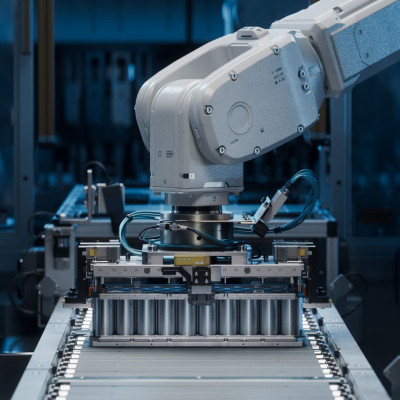

With the evolving capabilities of robotics, simple forms of artificial intelligence, more interconnected production systems, and emerging new business models, the client aimed to plan more systematically, build competence in these areas, and define a robotics strategy.

Project History

Presentation: Current Trends in Robotics

The workshop began with a presentation addressing the following questions:

What developments are occurring in robotics?

What is working well?

What aspects are less successful?

What are the future perspectives for the coming years?

Topics covered included:

Automated Guided Vehicles (AGVs)

Collaborative Robots (cobots)

Mobile Manipulators (combining cobots with autonomous platforms)

Machine Learning and Artificial Intelligence (AI) for Visual Inspection

Connectivity (e.g., MES/SAP, 5G)

New business models (e.g., leasing, Robots as a Service)

Group Discussion

In a group discussion format, coordinated with our client, we considered the following topics:

What opportunities exist?

What are the potential business cases?

Who are the internal service providers or customers?

What is the roadmap or the next steps for implementing the robotics strategy?

Outcome

During the workshop, ideas for applications for pilot projects were developed in detail. These projects enabled the company to progressively learn and enhance its robotics competence over time.